Ask Glen Johannesson to tell you the coolest part of his job and he laughs and says, “It’s all cool. I make flying robots.” Glen is Mechanical Architect for Aeryon Labs and a mechanical engineer.

Based in Waterloo, Ontario, Aeryon design Small Unmanned Aerial Systems (sUAS) for a range of applications around the world.

Aeryon Labs Glen Johannesson

Aeryon had its start in 2007, with the release of the Scout in 2009. The founders’ original idea was to develop a tool for collecting aerial imagery. The commercial market wasn’t quite ready to invest, but the military was, and they were the first to purchase the technology. By 2010, police services had begun to use the drones in traffic collision reconstruction. Taking photographs from the air helps with accurate measurements and capturing visuals like skid marks. Officers report that investigations that used to take two hours now take only 15 minutes, allowing them to clear scenes quickly and avoid the economic and social impact of road closures.

Designing for flight

Glen explains that designing a drone is about opposing needs – it has to be strong, but lightweight enough to fly. And of course, you have to be able to make it before you can make it fly.

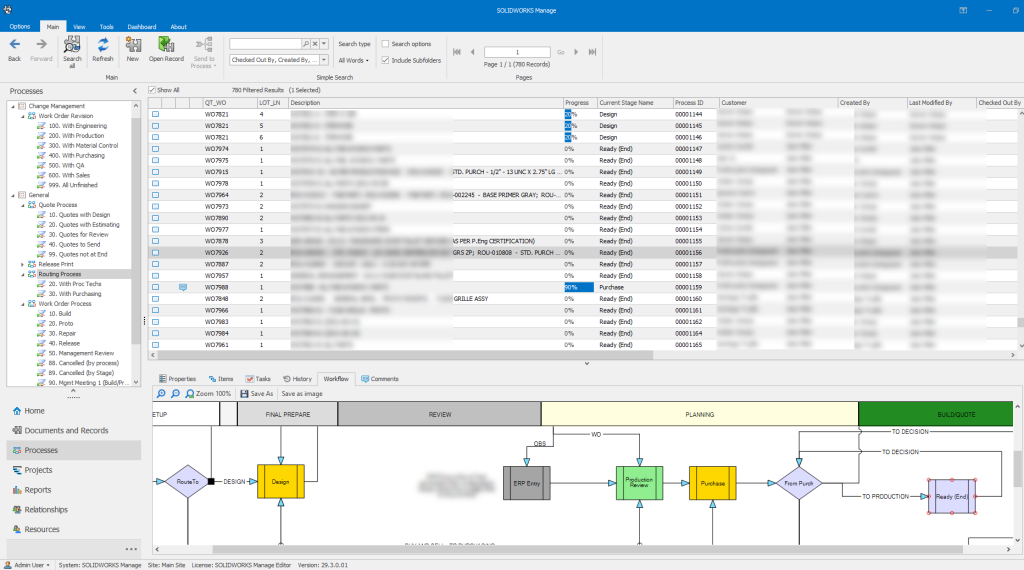

SOLIDWORKS® is the 3D design tool of choice for the engineers at Aeryon. They choose TriMech to provide and support the software, and ever since a smooth initial implementation, have expanded their SOLIDWORKS user base.

The benefit of clearly seeing designs in very early stages translates easily to savings, both in time and dollars.

“It can cost up to $15,000 to make a mold, so if we have to modify the design, it’s expensive,” Glen says. We used to cross our fingers a lot. If we can catch an issue early in SOLIDWORKS, and save that money, the software pays for itself in one situation.”

Not only did reducing the number of molds save money, particularly important in the early days when sales were just beginning to ramp up – but Glen was also able to combine parts, generating more savings and optimizing the aircraft’s weight and performance, and passing those savings and performance benefits on to the customer.

Picture of Elora Quarry from the sUAS

Lightweight and custom

The drone design is a complex, integrated system of hardware and software, designed to be easy for the pilot to operate using a tablet controller. It is built so that the propellers and legs can be transported attached to the aircraft or assembled in the field without tools, and if it takes a hard landing, these components can be easily snapped back on.

Aeryon Sky Ranger Package

Aeryon sUAS are in the five-pound range, with a bit of variance based on the weight of the camera payload, which is 10% of the craft’s total weight. Commercial customers operating in Canada and the U.S. are certified to fly based on certain weight classes so designing to keep it lean and light is critical.

Glen and his colleagues design all the components in SOLIDWORKS and assemble and test them in house. Aeryon’s partners make the molds and components.

Customization is key. Different customers have different requirements for the unit, from thermal sensors, to zoom lenses, to air quality measurement equipment, to the highest levels of encryption for security. Aeryon aircraft fly in 35 countries around the world, so other customizations ensure safe operations and compliance to airspace and government regulations.

Customer-driven drone design

Glen says working at the forefront of a new industry means working closely with users and potential users to advance the product and meet the current and future needs of customers. In the first year or two especially, customers were curious – and hopeful – about the applications.

“In the beginning, we needed feedback to help the customer be successful. Customers would say, ‘can you make it do this?’ and often we hadn’t even thought of ‘that’ yet. Our customers have helped to determine the functionality.”

It’s also been important for Aeryon designers to react quickly to customer problems in the field. One customer needed to fly close to high-voltage power lines but was unable to because of the sensitivity of the aircraft’s magnetic sensor. The team worked all weekend to redesign a new version of the drone that would briefly ignore the interference and the customer was able to get the job done.

Powerline Inspection

“They couldn’t believe we reacted so quickly, in just a few days,” Glen explains. “We used SOLIDWORKS to quickly modify the design to accommodate those unique needs.”

Glen also appreciates being able to show people detailed renderings on screen. Even if you’re not a mechanical engineer, you can easily see what the aircraft system is going to look like. Aeryon has even used rotating SOLIDWORKS images in a corporate video to help people understand the behind-the-scenes drone design process.

SOLIDWORKS renderings

“I can’t imagine doing this without SOLIDWORKS,” Glen says. “I used to start a design with pen and paper. Now, with the ease of sketching, assembling, and building in SOLIDWORKS, I just dive right in, even at the concept level.”

To learn more about Aeryon’s drone design, visit them online at aeryon.com.